December 8, 2023

What is a Flame Sensor and What To Do When It Goes Bad

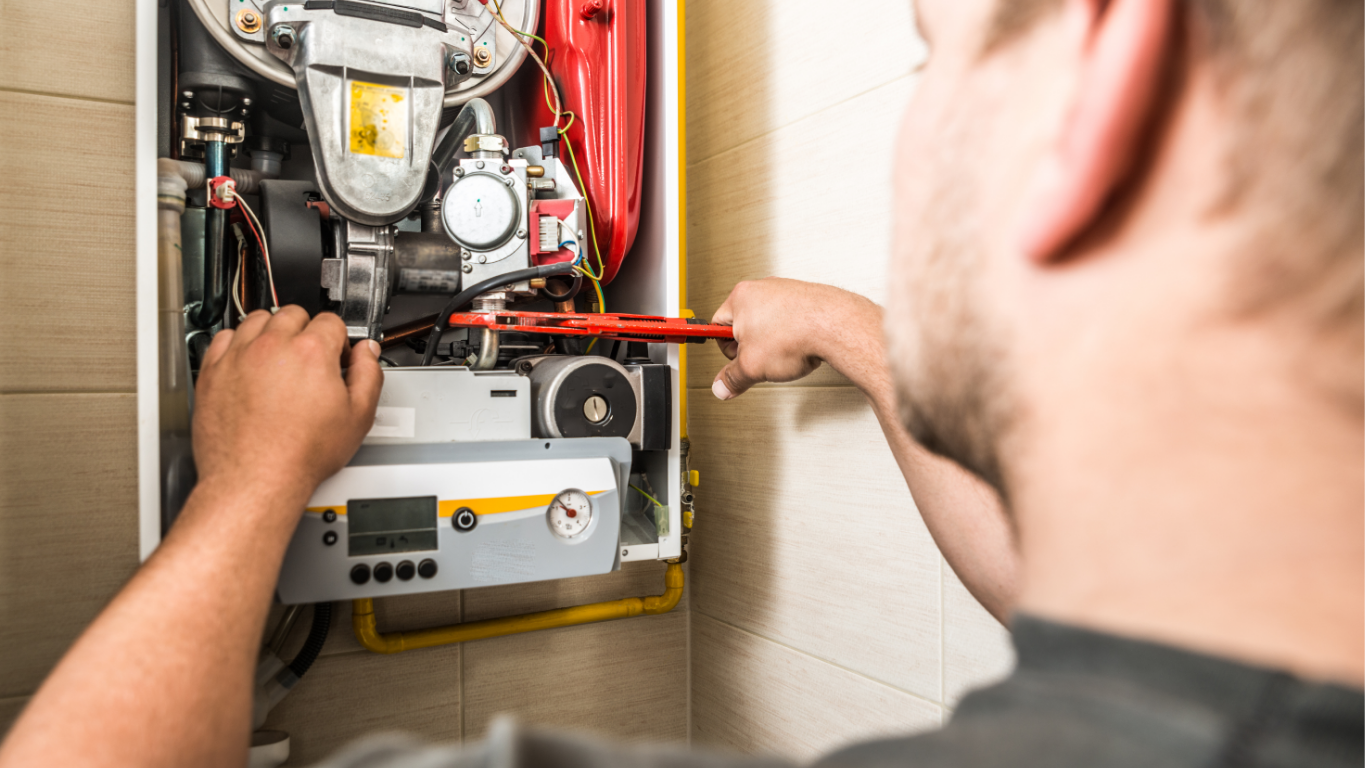

When it comes to the functionality and safety of your home’s heating system, a tiny but crucial component often goes unnoticed– the furnace flame sensor. This unassuming device plays a pivotal role in ensuring your furnace or boiler operates smoothly and, more importantly, without endangering your home.

Yet, many homeowners remain unfamiliar with what a flame sensor is and how to recognize when it goes bad. Join our heating repair experts from Bowman Mechanical Services in Raleigh, NC as we explore the importance of your gas furnace flame sensor and what to do when it goes bad.

What Are Flame Sensors?

A flame sensor is a vital safety device found in heating systems such as furnaces, boilers, and water heaters. Its primary purpose is to monitor the presence of a flame within the combustion chamber. By doing so, it ensures that the burner is igniting properly and that the flame continues to burn during the heating process.

What Types of Heating Systems Use Flame Sensors?

Flame sensors are a fundamental component of various heating systems, including:

Furnaces: Gas and oil furnaces commonly utilize flame sensors to monitor the burner’s flame and maintain safe and efficient combustion.

Boilers: Boiler systems, whether used for home heating or industrial processes, rely on flame sensors to regulate the burner’s operation and prevent potentially hazardous situations.

Water Heaters: Both tankless and traditional water heaters equipped with gas burners employ flame sensors to ensure the safe heating of water.

Common Signs of Flame Sensor Failure

When furnace flame sensors start to malfunction, it can lead to various issues within your heating system. Recognizing these common symptoms is crucial for timely HVAC repair services and preventing potential safety hazards.

Ignition Failure

One of the primary signs of a failing flame sensor is the inability of your heating system to ignite properly. If the sensor doesn’t detect the presence of a flame or sends inaccurate signals to the control board, the burner may not light at all, leaving you in the cold.

Frequent System Shutdowns

If you notice that your heating system frequently starts and stops without completing a heating cycle, this could be due to a problematic flame sensor. The furnace flame sensor failure to consistently detect the flame can cause the control board to shut down the system as a safety measure.

Inconsistent Heating

When a furnace flame sensor isn’t functioning correctly, it may allow the burner to ignite, but the flame might not burn consistently. This can result in uneven heating, with some areas of your home feeling colder than others. Inconsistent heating can also lead to increased energy consumption and utility bills.

Importance of Prompt Diagnosis of Malfunctioning Flame Sensors

Promptly addressing and diagnosing issues with your furnace flame sensor is crucial. Let’s look at How furnace maintenance or flame sensor replacement and repair are important for your home.

Safety

A malfunctioning flame sensor can compromise the safety of your heating system. Ignoring the problem could lead to gas leaks, unburned fuel accumulation, or even the risk of fire or carbon monoxide poisoning exposure.

Energy Efficiency

When your heating system doesn’t operate optimally due to a faulty furnace flame sensor, it can consume more energy and result in higher heating bills. Fixing the sensor can lead to improved energy efficiency and cost savings.

Preventing Further Damage

Ignoring the signs of a bad flame sensor can lead to more extensive damage within your heating system over time. Addressing the issue promptly can prevent costly repairs or the need for a HVAC system replacement.

Comfort

Inconsistent heating and frequent system shutdowns can make your living space uncomfortable. Timely furnace flame sensor diagnosis and repair can help maintain a consistent and comfortable indoor temperature.

What Causes Gas Furnace Flame Sensor Issues?

Several factors can contribute to the malfunctioning of a furnace flame sensor. Understanding these factors is essential for effective troubleshooting and maintenance of your heating system.

Buildup of Dirt and Debris

Over time, dust, soot, and other airborne particles can accumulate on the surface of the flame sensor. A dirty flame sensor insulates it from the heat of the flame. This insulating effect reduces the sensor’s ability to generate the necessary electrical current when exposed to the flame. As a result, the control board may interpret this as a lack of flame, leading to system shutdowns.

Oxidation and Corrosion

Flame sensors are typically made of metal, and exposure to combustion gases, moisture, and air can lead to oxidation and corrosion. When the sensor’s surface becomes corroded or coated with oxidation, it can hinder its conductivity and responsiveness.

Poor Sensor Positioning

Incorrect sensor positioning can result in the furnace flame sensor not being exposed to the flame’s heat properly. If it’s too far from the flame, it may not generate a strong enough current for detection. Conversely, if it’s too close to other hot components, it may overheat or become damaged, affecting its performance.

When to Replace a Furnace Flame Sensor

While routine furnace flame sensor cleaning can often address minor issues, there are certain indicators that cleaning alone may not suffice. In such cases, it may be necessary to consider replacing the flame sensor for optimal performance and safety.

Cracks or Breaks

Inspect the flame sensor carefully for any visible cracks or physical damage. If you notice significant damage to the sensor, cleaning alone is unlikely to restore its functionality. Physical damage can compromise the sensor’s ability to detect the flame accurately.

Burn Marks

Examine the sensor’s surface for flame burns or signs of excessive heat exposure. Prolonged exposure to high temperatures can cause irreversible damage to the sensor, affecting its conductivity and performance.

Old Age of the Sensor

Flame sensors, like all components, have a finite lifespan. If your hot surface ignitor is several years old and has undergone regular wear and tear, it may be nearing the end of its functional life. Over time, the materials used in the sensor can degrade, leading to reduced sensitivity and reliability. Staying aware of your furnace’s lifespan is important to knowing when a replacement or repair is due.

Troubleshooting Flame Sensor Issues

In addition to recognizing the signs of a bad flame sensor and understanding its causes, there are further troubleshooting steps you can take to identify and resolve flame sensor issues.

Check Electrical Connections

Ensure that the electrical connections to the flame sensor are secure and free from corrosion. Loose or corroded connections can disrupt furnace breaker from performing its job of transmitting signals to the control board. Carefully inspect the wiring leading to the flame sensor for any frayed or damaged wires, and replace them if necessary.

Verify Gas Supply

Confirm that there is a steady supply of gas to your heating system’s gas valve. An insufficient gas supply can lead to ignition problems or cause the flame to go out, which the flame sensor will detect as an issue. Check for any leaks or blockages to the furnace’s gas valve and related components that might be affecting the burner’s performance.

Assess the Control Board

Examine the furnace access cover of your heating system for any visible signs of damage or malfunction. The heating system’s control board plays a critical role in interpreting the signals from the furnace flame sensor and regulating the burner. If you suspect a control board issue, consult your system’s documentation or a professional HVAC technician for guidance on further diagnostics and potential replacements.

Consult an HVAC Technician

While some troubleshooting steps can be performed by homeowners, there are instances where it’s advisable to consult a qualified HVAC technician from Bowman Mechanical Services:

Limited HVAC Knowledge: If you are not familiar with the inner workings of your furnace’s heating system or lack experience in HVAC repair, it’s best to seek professional help. Attempting complex repairs without the necessary expertise can lead to further damage or safety hazards.

Persistent or Complex Issues: If you’ve tried basic troubleshooting steps and the problem with your flame sensor persists or appears to be more complex, it’s time to call in a technician. They have the tools, experience, and knowledge to diagnose and resolve intricate issues effectively.

Safety Concerns: If you suspect gas leaks, carbon monoxide leaks, or other safety-related issues, do not attempt to resolve them yourself. Evacuate your home, turn off the gas supply if possible, and contact emergency services and an HVAC technician immediately.

Warranty Considerations: If your heating system is still under warranty, attempting DIY repairs without professional guidance could void the warranty. In such cases, it’s best to have a technician handle the repairs to maintain warranty coverage.

Schedule Flame Sensor Maintenance Services with Our HVAC Experts

Don’t wait for your heating system to leave you in the cold. Ensure the safety and efficiency of your home’s heating by scheduling furnace flame sensor maintenance services with our experienced HVAC experts today.

With the professional care and attention to detail provided by Bowman Mechanical Services in Raleigh, NC you can enjoy worry-free warmth throughout the winter.

Contact us now to book an appointment and keep your heating system running smoothly by calling [phone] or filling out the form below to get started.